Exploring the Intersection of 3D Printing, Modeling, and Mini PCs: A Comprehensive Guide

In recent years, 3D printing has rapidly evolved from a niche hobby to a mainstream technology that offers vast possibilities for both professionals and enthusiasts alike. As the maker movement continues to gain momentum, individuals are exploring the potential of 3D printing technology in various applications, including prototyping, crafting custom parts, art, and design. However, diving into the world of 3D printing requires not only the right equipment but also supportive computing power. In this blog post, we will discuss the requirements for a suitable PC for 3D printing tasks, focusing on what it means to utilize Software like Orca Slicer and Fusion 360. We’ll also explore some recommendations for mini PCs, including the Dell OptiPlex 7040, and share essential insights for anyone looking to step into the realm of 3D printing.

The Growing Popularity of 3D Printing

3D printing, also known as additive manufacturing, is a technology that enables the creation of physical objects from digital files. This process typically involves the layering of materials—such as plastic, metal, or resin—based on a three-dimensional model created using computer-aided design (CAD) Software. The technology appeals to a range of audiences, from hobbyists creating custom toys to engineers producing prototypes for testing.

Benefits of 3D Printing

Here are some of the notable advantages of 3D printing:

- Customization: Users can create tailor-made parts or products tailored to specific needs.

- Cost-Effective Prototyping: Rather than sourcing expensive molds or tools, 3D printing allows for rapid prototype creation, significantly reducing costs.

- Sustainability: Many 3D printing materials are more environmentally friendly, and the processes typically generate less waste than traditional manufacturing.

Diverse Applications

3D printing is versatile, giving rise to various applications, including:

- Medical Devices: Custom prosthetics and implants can be designed and produced using 3D printers.

- Architecture: Models and architectural features can be printed for better visualization.

- Fashion: Designers are employing 3D printing to create innovative clothing and accessories.

Understanding the Software Needs

Before diving into the hardware side of 3D printing, it’s crucial to understand the software requirements. Among the most popular software solutions in the 3D printing community are:

Orca Slicer

Orca Slicer is a tool for preparing 3D models for printing. It converts a 3D model file format (usually STL) into G-code that a printer understands. Key features include:

- Easy User Interface: It provides an accessible interface for beginners while offering advanced settings for experienced users.

- Customization Options: Users can adjust layer heights, print speeds, and temperatures to fine-tune the printing process.

Autodesk Fusion 360

Fusion 360 is a powerful CAD tool favored by many designers and engineers. It allows users to create complex 3D models and simulations. Some notable features include:

- Collaboration: Built-in tools for team collaboration make it easy to share designs.

- Integrated Manufacturing Tools: Users can switch between designing and preparing models for 3D printing seamlessly.

Both Orca Slicer and Fusion 360 have specific hardware requirements that must be met for optimal performance.

System Requirements

Here’s a brief overview of the recommended specifications for running these applications smoothly:

- Processor: A multi-core processor (Intel i5 or equivalent) is ideal.

- RAM: At least 8GB of RAM is generally recommended for handling larger models.

- Graphics Card: A dedicated graphics card (NVIDIA or AMD) supports complex rendering and visual tasks.

- Storage: SSD storage can significantly improve loading times and help manage files efficiently.

Choosing the Right Mini PC for 3D Printing

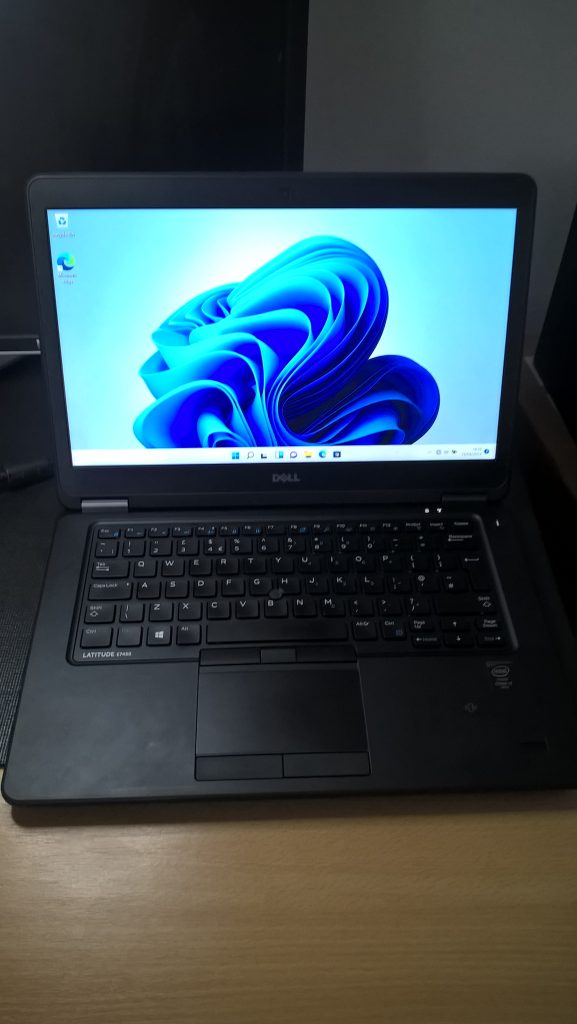

With the knowledge of the software requirements, the next step is to choose the right mini PC capable of handling these tasks efficiently. The Dell OptiPlex 7040 Micro PC has caught the attention of several 3D printing enthusiasts. Let’s delve deeper into its specifications and capabilities.

Dell OptiPlex 7040 Micro PC Overview

The Dell OptiPlex 7040 Micro is a compact desktop solution designed primarily for office settings, but its specs can also support demanding graphic and design tasks associated with 3D printing. Here are some of its specifications:

- Processor Options: It often comes equipped with Intel Core i5 or i7 processors, providing sufficient processing power for most 3D applications.

- Memory: The OptiPlex typically offers 8GB or more of RAM, which meets the requirements for the mentioned software.

- Storage: SSD options are available, enhancing load times and overall performance.

- Compact Design: The micro form factor means it can easily fit into small workspaces.

Performance Insights

-

Processing Power: The OptiPlex’s processor is adequate for running software like Orca Slicer and Fusion 360, allowing for comfortable modeling and slicing experiences without significant lags.

-

Upgrade Potential: While the base model may come with 8GB RAM, users can upgrade this component down the line if they require more power, especially when handling more complex models.

-

Affordability of Refurbished Models: Opting for refurbished versions of the OptiPlex provides significant savings, allowing users to invest in a capable machine without breaking the bank.

Alternative Mini PC Options

While the Dell OptiPlex 7040 Micro is a solid choice, numerous alternatives can also cater to the needs of a 3D printing setup:

-

Intel NUC Series: These mini PCs are compact and customizable, with options to include powerful processors and RAM configurations that support various applications.

-

Asus PN Series: Known for their reliability, Asus offers mini PCs that can be equipped with various Intel processors, RAM, and storage options, making them adaptable for 3D printing tasks.

Consideration of Graphics Cards

While many mini PCs come with integrated graphics, investing in a model that allows for a dedicated GPU can significantly enhance modeling experiences, especially in software like Fusion 360 when rendering complex designs. Several mini PCs support low-profile graphics cards, providing an additional boost to performance.

Evaluating Your Needs: Simplicity vs. Power

When considering a mini PC for 3D printing, evaluate what your primary needs will be:

-

Ease of Use: If you are new to 3D printing and primarily need a device for basic tasks, simpler setups will work just fine. Mini PCs, including the Dell OptiPlex, are likely suited for handling simple tasks without overkill.

-

Future Growth: However, if you anticipate expanding your projects or using more advanced software, opting for a more powerful PC with upgrade options may be worth the investment.

Final Thoughts: Community and Support

With the rapid evolution of technology and the community surrounding 3D printing, it’s essential to leverage resources like forums, social media groups, and specialized networking sites to gain insights and support. Online communities, such as those on Reddit, can offer valuable information and personal experiences to help others make informed decisions on equipment and best practices for 3D printing.

In conclusion, as you explore the exciting world of 3D printing, make sure to choose a mini PC that meets your specific needs, weighing the benefits of affordability against the performance power required for your tasks. By investing in the right setup—whether it be the Dell OptiPlex 7040 Micro or a suitable alternative—you will be well on your way to creating incredible three-dimensional prints that bring your ideas to life. So, fire up that 3D printer and let your creativity flow!

Share this content:

Response to “3D Printing, Modeling, and Mini PCs”

Thank you for this insightful article on the intersection of 3D printing, modeling, and mini PCs. It indeed encapsulates the vast potential of 3D printing technology and the critical role of Software and hardware in enhancing this process.

As you rightly pointed out, selecting an appropriate mini PC like the Dell OptiPlex 7040 is vital for optimal performance when running Software such as Orca Slicer and Fusion 360. I’d like to add that when evaluating mini PCs, also consider the following:

For novice users, I’d recommend starting with a more user-friendly interface in Orca Slicer, as the setting adjustments can significantly impact print quality. For experienced users, experimenting with Fusion 360’s advanced simulation features can yield impressive design improvements.